Wuxi Huizhenhai Trade Co., Ltd. is a leading player in the building materials industry. With a commitment to quality and innovation, we offer a wide range of high-grade products to meet the diverse needs of our customers. From construction materials to interior finishes, our extensive product line caters to various building projects.

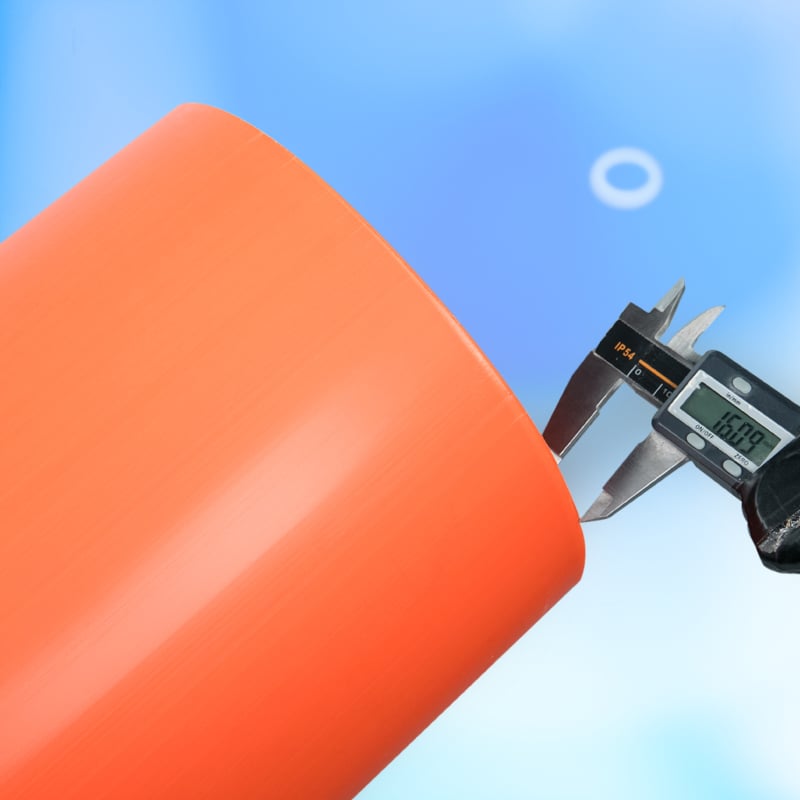

The main component of MPP power cable conduit system is modified polypropylene material. This material is extremely resistant to chemical corrosion and thermal stability, and can be used over a wide temperature range. At the same time, the material also has high pressure resistance and good toughness, which is mainly used in the trenchless construction field of urban power grid and information communication pipe network to make up for the shortage of PVC power cable conduit system