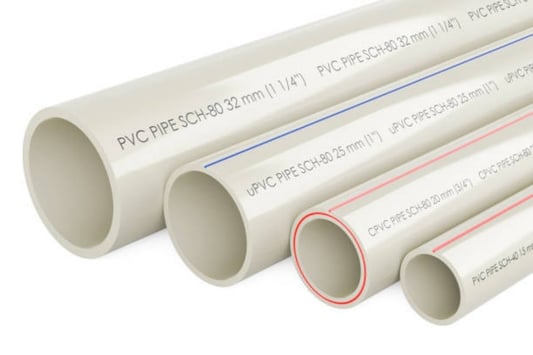

IntroductionFor those who are not familiar with construction materials, 4 inch schedule 40 might seem like a confusing term. However, it's a very important concept to understand for anyone who works with pipes or structures that require precision and strength. In this article, we'll explore what 4 inch schedule 40 means, its applications, and why it's important to choose the right materials for your specific needs.What is 4 Inch Schedule 40?Simply put, 4 inch schedule 40 refers to the thickness of a pipe, specifically its wall thickness. It's a standard size used in the construction industry, and the schedule number indicates the thickness of the pipe walls. For 4 inch schedule 40, the thickness is 0.237 inches, which is close to 6mm.Applications of 4 Inch Schedule 40There are many applications for 4 inch schedule 40 pipes, including plumbing, heating and cooling systems, and even in the manufacturing of furniture and vehicles. It's a versatile size that can accommodate a range of liquids and gases, and it's often used in large-scale construction projects like buildings and bridges.Strength and DurabilityOne of the reasons 4 inch schedule 40 pipes are so popular is due to their strength and durability. Because of their thickness, they're less likely to deform or break under pressure, and they can withstand extreme temperatures and weather conditions. This makes them ideal for use in harsh environments and heavy-duty applications.Choosing the Right MaterialsIt's important to choose the right materials when working with 4 inch schedule 40 pipes. Depending on your specific needs, you may want to consider different materials like PVC, steel, or copper. PVC is a popular choice because it's lightweight and easy to work with, while steel is known for its strength and durability. Copper is often used in plumbing applications because it's resistant to corrosion and easy to solder.Installation and MaintenanceProper installation and maintenance are crucial for ensuring the longevity and efficiency of 4 inch schedule 40 pipes. The pipes must be installed correctly to prevent leaks and ensure proper flow of liquids and gases. Regular inspections and maintenance can help identify any issues before they become major problems, and can extend the life of the pipes.The Importance of ComplianceIt's also important to comply with local and national building codes when working with 4 inch schedule 40 pipes. These codes ensure that the materials and installation methods are up to industry standards and are safe for use. Failure to comply with building codes can result in fines and legal action.Cost ConsiderationsThe cost of 4 inch schedule 40 pipes can vary depending on the materials and manufacturer. PVC is generally the most affordable option, while steel and copper are more expensive but offer greater strength and durability. When considering cost, it's important to also factor in the longevity and efficiency of the materials.Environmental ImpactsThe production and disposal of 4 inch schedule 40 materials can have environmental impacts. PVC, for example, is made from petrochemicals and can release toxic chemicals when heated or burned. Steel production also requires a significant amount of energy and resources. As such, it's important to consider eco-friendly alternatives when possible.Conclusion4 inch schedule 40 pipes are an important component in many construction applications. Understanding their thickness, applications, and the materials used is crucial for ensuring proper use and installation. By choosing the right materials and complying with industry standards, you can build strong, durable, and efficient structures that will last for years to come.Quote InquiryContact Us