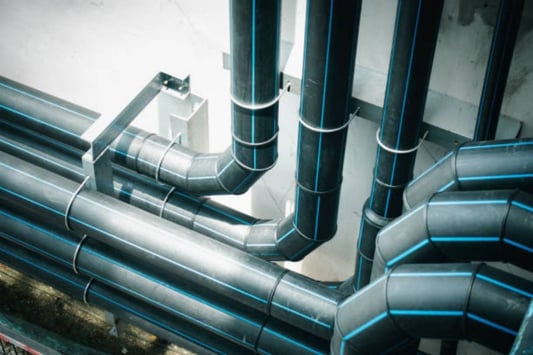

What is pvc to pe pipe connection?Joining PVC and PE pipes can be a difficult, if not impossible, process without a proper understanding of how the two materials differ. PVC is a rigid material, while PE is a flexible plastic, which makes creating a connection between the two challenging. PVC to PE pipe connection, hence, refers to the process of joining these two materials to ensure a strong and durable connection. Understanding the Importance of PVC to PE Pipe ConnectionWhen PVC and PE pipes are used in the same plumbing system, a strong connection is vital for maintaining the integrity of the entire system. A weak or faulty connection could lead to leaks, cracks, or system failures, which will inevitably lead to additional expenses and headaches. The importance of a strong PVC to PE pipe connection cannot be overemphasized.Choosing the Right Connection MethodThere are different methods that can be used to join PVC and PE pipes, but choosing the right one can make all the difference in ensuring a lasting and solid connection. Some of the most popular techniques include butt fusion, electrofusion, and mechanical coupling. Each of these techniques involves specific procedures and tools, and selecting the right option depends on various factors, including the diameter of the pipes, the application, and the budget.Preparing the Pipes for ConnectionBefore starting the connection process, the pipes must be properly prepared to ensure a seamless and tight connection. The pipes should be clean, dry, and free from any debris or damage that could weaken the connection. The outer surface of the PE pipe should also be lightly sanded to ensure a good grip for the fitting.Steps for Butt Fusion But-fusion is a popular connection method for PVC to PE pipes. Here are the general steps involved in butt fusion:Trim the ends of both pipes to create flat and square surfacesPlace the pipes in the fusion machine to heat them upApply pressure to both ends of the pipes and wait for them to fuseAfter fusion, carefully remove the pipes from the machine and allow them to coolSteps for ElectrofusionElectrofusion is another method of joining PVC to PE pipes, which involves the use of an electric fusion machine to create a solid connection. Here are the general steps involved in electrofusion:Clean and mark the pipe ends to be joinedSlide the fitting onto the PE pipeConnect the Electrofusion machine to the fitting and pipe ends with the appropriate couplingsAllow the machine to fuse the fitting to the pipe ends as per the manufacturer’s specificationAfter completion, allow the joint to cool and test for leaksSteps for Mechanical CouplingMechanical coupling is a relatively simple and cost-effective way to connect PVC to PE pipes. Here are the general steps involved in mechanical coupling:Sand the outer surface of the PE pipe to allow the coupling to gripSlip the mechanical coupling over the end of the PE pipeInsert the PVC pipe into the other end of the coupling until it reaches the middle of the couplingTighten the bolts of the coupling to form a firm connection between the PVC and PE pipesPost-Connection ChecksAfter connecting the PVC to PE pipes, it is essential to conduct a thorough check to confirm that the connection is solid and free from leaks. This can be done by conducting a hydrostatic pressure test or air pressure test, depending on the size and application of the pipes. It is recommended to test the connection at least twice to ensure its strength and durability.ConclusionMaking a PVC to PE pipe connection can be a challenging process, but with the right tools, knowledge, and techniques, it is possible to create a lasting and secure connection that can withstand the test of time. By following the steps outlined above, you can ensure that your pipes are adequately connected and working efficiently.Quote InquiryContact Us